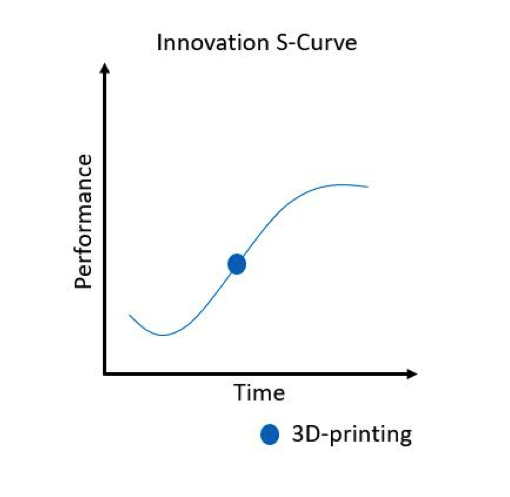

In business and operational management, the S-curve represents the process of innovation that technologies undergo. It is used to examine whether technology is performing adequately and how it may compare to the existing alternatives. The key takeaways top stakeholders might extract from using the S-curve concern the level of maturity of the technology in question, which then allows them to adjust their expectations accordingly. Almost any innovation from recent years might be analyzed within the S-curve framework, but for the purposes of this assignment, a well-known and widely utilized example was chosen. This paper briefly discusses one of the most famous modern innovations, 3D printing, with the perspective of the S-curve applied to it.

Despite recently experiencing a boom with customers beginning to print essential household apparel and, more importantly, medical prosthetics, the 3D printing technology is far from being new. Its origins can be traced back to 1986, with the technology originally being named stereo-lithography. Originally heavily marketed toward scientists and laboratory workers, modern 3D printers continue to become friendlier to the general public. At the moment, the private use of technology is limited to the world of crafting hobbies, but the business landscape has already begun to evolve in response to the 3D printing renaissance.

Businesses are transitioning from mass manufacturing to mass personalization, with their capacity to personalize the output greatly increased by 3D printing technology. DIYers and researchers alike are attempting to access a 3D printer for their consistent personal use. At the same time, the laboratory application of the innovation is far from stagnating, particularly with the recent advancements in organ and food printing. The latter segment of potential applications for the titular technology has the capacity to evolve endlessly, preventing the technology itself from entering the stagnation phase on the S-curve.

When the evolving scientific landscape is taken into account, it becomes evident that the innovation’s relevancy now is maybe higher than ever. According to PricewaterhouseCoopers, 3D printing in the near future will undergo a price reduction and will therefore become more accessible to the general public. Similarly, the laboratory-based customers of the titular innovation would be able to optimize their research processes with almost endless opportunities for optimization. According to recent predictions, the worldwide 3D industry will expand at a rate of 20% per year, reaching $8.6 billion by 2023. As a result, the industry has a long way to go before it was to reach a stagnation point.

The transformative nature of using 3D printing for medicine and food production cannot be overstated. It provides an almost unique solution to the extreme income inequality on a worldwide scale since, with 3D printing, additional foods might be manufactured in addition to the other tactics used to address the problem of world hunger. Similarly, the technology’s application in medicine and, in particular, tissue generation guarantees its relevancy for the healthcare sector within years to come. The business landscape, in general, begins to regard 3D printing with ever-increasing trust, which now has the capacity to leave the boundaries of hobby-related small-scale productions.

Although current 3D printing capabilities aren’t suitable for every type of product, they already provide a viable alternative to traditional manufacturing methods and procedures, disrupting the status quo and further securing the interest of the global business environment towards the technology.

Reference

Hanke, P. (2021). 3D-printing: Past, present & future of innovation in progress | CBS. Web.